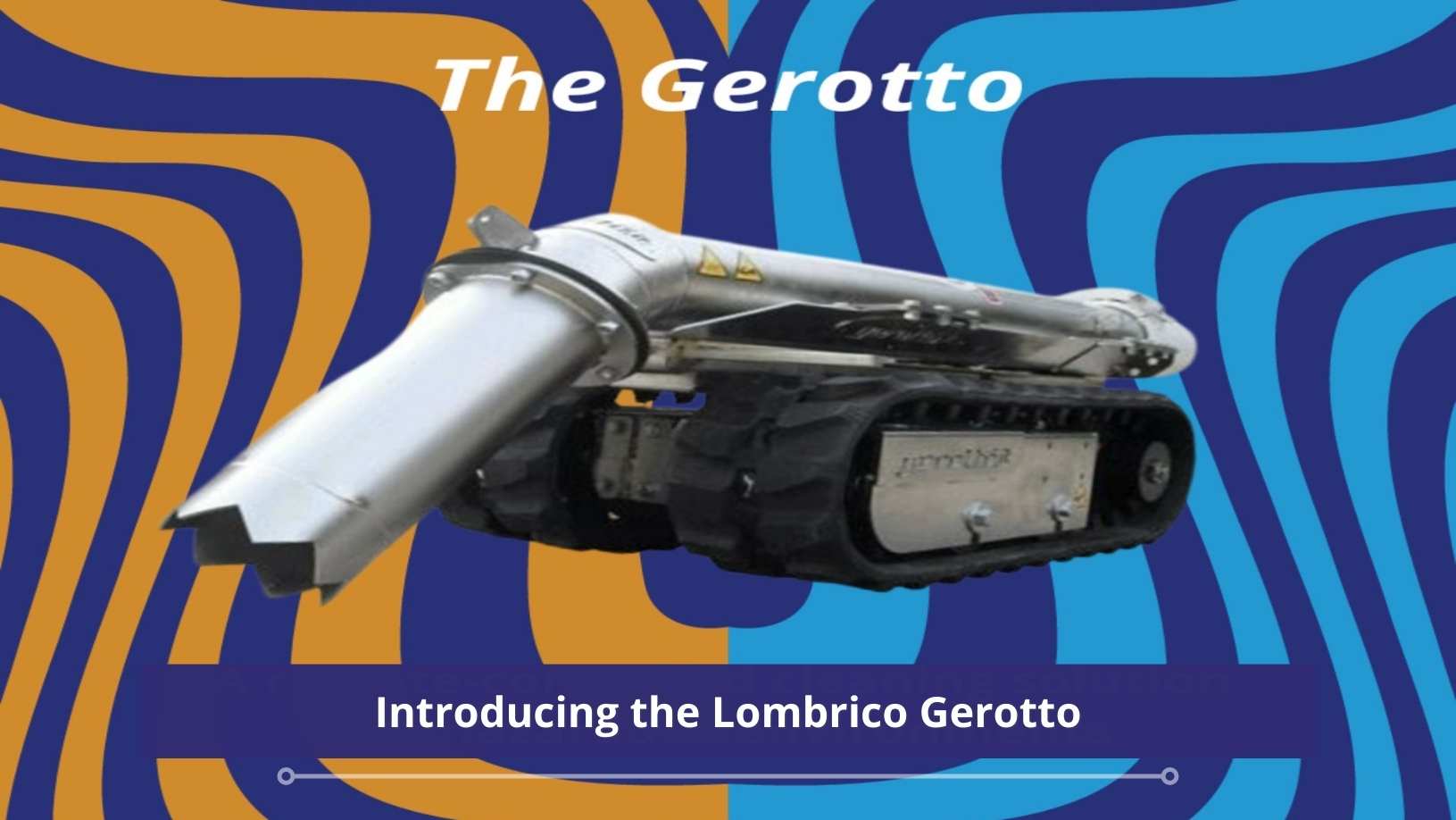

Introducing the Lombrico Gerotto

Here at McBreen Environmental we try to stay up to date with the latest technology & equipment to ensure every job is done to get immaculate results while also making it as safe as possible. Using the state-of-the-art ROV, the Gerotto is the perfect suction cleaning solution for hazardous and hard-to-reach environments, whilst also reducing the confined space risk by keeping operators at a safe distance from dangerous, hazardous materials and environments.

The state-of-the-art Gerotto is equipped with:

- Two hydraulically driven rubber tracks

- Hydraulic manual manifold for precise and accurate movement & control

- Durable stainless-steel structure

- Connection system for an external hydraulic source

- Video inspection system

- Multiple attachments, for different situations – sludge nozzle, bora nose, high-pressure nozzles and auger

- Suction ranges from 80mm to 250mm

With all these features the Gerotto can effectively suction all types of materials, debris, dust, wet obstructing sewer pipes, tunnels, tanks, spaces underneath conveyor belts.

Key benefits:

- Increased safety for employees: Allows operators to control the cleaning process from a safe distance, reducing the risk of exposure to hazardous materials or employee accidents and incidents.

- Improved efficiency: advanced technology facilitates the cleaning process more effectively and quickly than traditional methods, reducing man entry hours and plant stoppage time.

- Cost saving: reduced labour costs by reducing the number of people and time needed to complete a cleaning task.

Case Study – Stratford London

Scope of Works –

Cleaning of 8 culverts approx. 2.7m in diameter and 60 meters long using robotics and vacuum with a confined space team.

- To minimize the amount of time and labour required working in a confined space environment.

- Find a solution that will not cause any structural damage to the existing culverts during the desilting process.

- Create safer working conditions and reduce the requirement of highly intense manual labour that is traditionally required for a project like this.

- Reduce the project duration.

Pre – Commencement

Prior to commencing works on site, two openings were created to facilitate forced ventilation during the barrel cleaning process and ensure technicians and equipment could be lowered in a safe manner.

Commencement of Works

Once the team were in place the work commenced

- Most barrels had approx. 800mm of silt located in them. Each day the team were able to clean approx. 10-15m of the barrel.

- During the cleaning process special care & attention was taken to ensure the structural integrity of the barrel was not compromised throughout the cleaning process.

- Technicians operated the Gerotto by remote control at the rear of the Gerotto and rotated on an hourly basis with the 2 top men.

- Once DISAB was filled with waste it was tipped into a skip and brought for disposal to a licensed waste facility for disposal.